Manual

Process Line

The manual process line is a core production system that transforms magnesium scrap into high-quality alloys

through skilled operation and precise procedures.

This line is manually controlled from input to final product packaging,

optimized for strict quality management and customized mass production.

STEP 1

Scrap Input

and Sorting

STEP 2

Melting

STEP 3

Alloying Element Input

and Composition Control

STEP 4

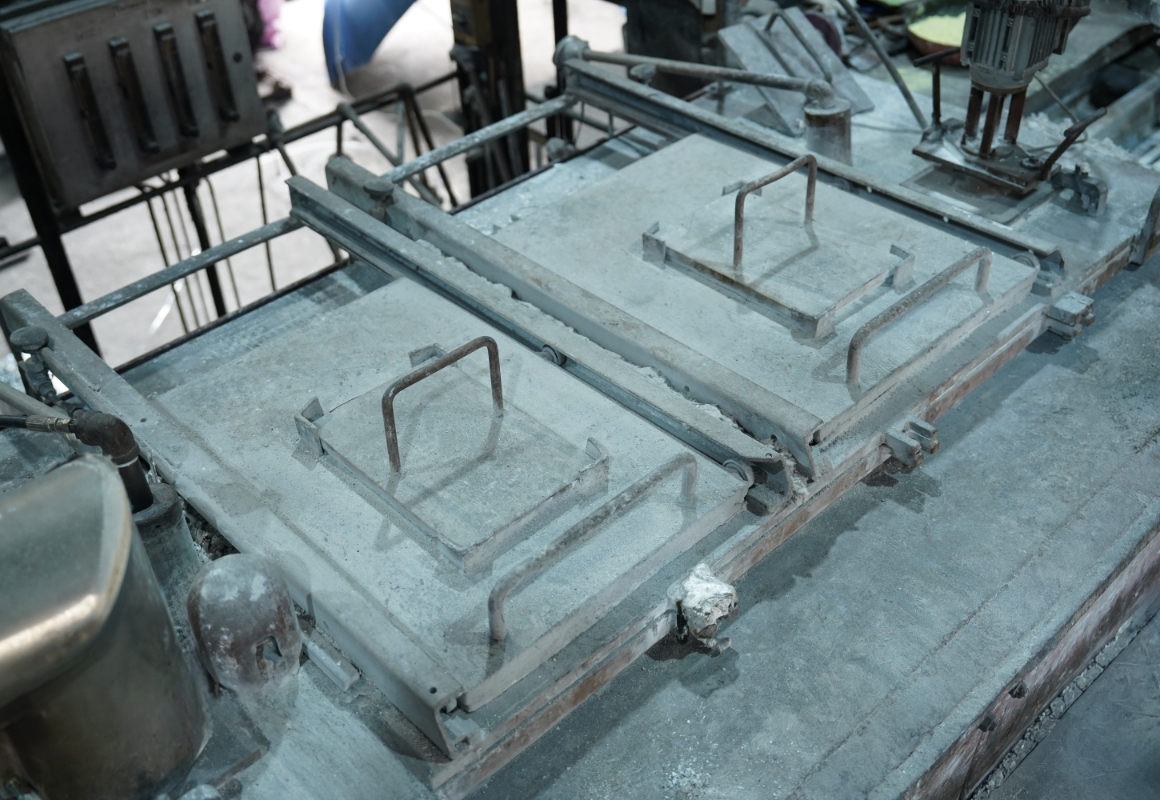

Pouring

and Finishing

STEP 5

Packaging

and Shipment

Scrap Input and Charging

Melting

Alloying Element Input

and Composition Control

Chemical Analysis

Pouring and Finishing

Chemical Analysis

Packaging and Shipment